Your skid steer is critical, but you must operate it properly to get everything you want from it. Operating a skid steer effectively and driving one are two different concepts. From how to turn it on and off properly to various control schemes and best safety practices, this how-to guide explains all you need to know about operating your skid steer.

How to Use a Skid Steer

Before you can operate a skid steer effectively, you need to know the basics of how to use it. You’ll want to understand what it can do and some basic terminology.

A skid steer is a versatile piece of equipment commonly used in landscaping and construction projects. The name comes from its wheels, which are fixed in one direction. The only way to turn it is to apply more speed to one side of the vehicle, causing the wheels to “skid” into a new direction when turning, or to put one side in forward and the other in reverse.

Skid steers have a load capacity ranging from 800 pounds to more than 2 tons. Despite their strength, they are lightweight and easy to move around. They are suitable for many tasks thanks to the numerous attachments you can equip to them.

There are three categories of skid steers:

- Small frame: These weigh less than 1,750 pounds with under 50 horsepower. They are ideal for smaller projects like landscaping work, site development and underground construction jobs.

- Medium frame: These weigh between 1,750 and 2,200 pounds with 50 to 70 horsepower engines. These are the most popular types of skid steer used in the construction industry.

- Large frame: Large frame skid steers weigh over 2,200 pounds with engines exceeding 70 horsepower.

The last important terminology to understand is the difference between radial and vertical lifts.

- Radial lift: The traditional skid steer type, radial lifts are known for their simple setup. These lifts feature a single pivot point that lifts the boom. The arm moves in a circular, C-shaped curve when raised. The reach is at its furthest point when the boom is in front of the operator. The shortest reach is when the bucket is at the top of its arch.

- Vertical lift: Vertical lift loaders are the best choice if you are looking for optimal strength and lift capacity. It also has more vertical reach. Instead of a C-like curve path when lifting, they lift upwards on a straight path. The intricate design of the boom provides a consistent reach along the lift trajectory.

Pre-Operation Inspection

Before getting in your skid steer, perform a thorough pre-operation check. These checks are done to avoid unnecessary damage, mechanical issues or downtime. You need to complete three inspections: a 360-degree walk around the vehicle, a component check and a system check in the operator’s seat.

Walk Around Inspection

This should always be the first pre-operation inspection you perform. Follow the items on this checklist to conduct a thorough walk-around inspection of your skid steer.

- Windows: Ensure your windows, windshield, mirrors and any other glass have not been damaged.

- Cage: Ensure all rollover protection and the cage are in good condition and show no signs of damage or compromise.

- Cylinders and hoses: Check that your cylinders are not leaking. Your hoses and lines must also be dry and clean.

- Grease points: Inspect machine parts that should be greased up. If they are dry, apply more grease and check bolts and pins simultaneously.

- Dirt: Remove any rocks or debris from the tires and other skid steer parts and clean any dirty areas.

- Exhaust system: Your exhaust system and radiator fans must be unobstructed, undamaged and clean.

- Attachments: Double-check that your attachment is secured before starting the skid steer. Give it a thorough visual inspection and ensure everything is in good condition.

Component Checks

Once your walk-around inspection checklist is complete, it’s time to move on to your component checks. Look over the following areas during this inspection:

- Fluid levels: Check your hydraulic fluid, coolant and oil levels, ensuring everything is at the fill line.

- Engine bay: Inspect your engine bay. Keep an eye out for any signs of damage, and make sure nothing is sticking out. This area must look normal and in good condition before you turn your skid steer on.

- Air filters: Clean the air filters every week, and check for debris in the filters every time you use your skid steer. Ensure your air intake shows no signs of damage.

- Radiator fins: Inspect the radiator fins, and look for any signs of damage on the coils.

Inspection From the Operator’s Seat

This is the shortest of the checklists. When in the operator’s seat, look for:

- Warning lights: When you turn the key, one click will display any warning lights or indications of an issue on the dashboard. After a quick inspection, you can fully turn on the machine. This will show everything from warning lights to error messages. If anything serious appears, turn off the machine immediately.

- Owner’s manual: You should familiarize yourself with the important icons and messages on the dashboard. If you see any you don’t recognize, look them up in the owner’s manual and act accordingly.

- Engine noises: Let the engine run briefly when you turn the skid steer on. Listen out for any unusual noises or irregularities, such as odd idling sounds, loud noises or signs of grinding. If you hear strange noises, diagnose them further before using the machine.

- Gauges: Check the heat and fuel levels before you start moving.

How to Start and Shut Down a Skid Steer

The first step to mastering skid steer controls is learning to turn the machine on and off. The pre- and post-operation inspections are not the same as knowing how to start the machine. These inspections are only the first step in the starting process.

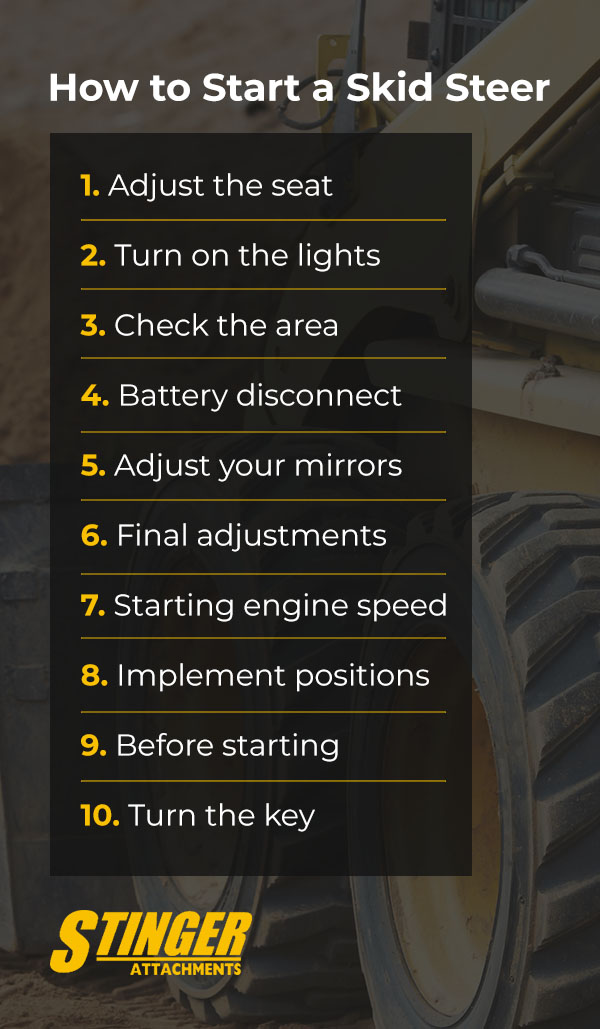

How to Start a Skid Steer

Follow these steps to start your skid steer vehicle:

- Adjust the seat: After you get in the skid steer and complete your inspections from the operator’s seat, the next step is to adjust your seat. You want to adjust the seat so you are comfortable sitting on it and can achieve full pedal travel and efficient reach.

- Turn on the lights: Turn on the lights needed for your driving conditions, such as driving in the evening, at night or in the fog.

- Check the area: Make sure nobody is in front of the machine, under the tracks or near the machine before you start driving. Sound your horn to signal to anyone in the area that they need to move.

- Battery disconnect: Ensure the battery disconnect switch is turned on if your skid steer is equipped with this feature.

- Adjust your mirrors: Double-check that your mirrors are in the right position to maximize your field of vision. Familiarize yourself with your blind spots.

- Final adjustments: Make any further adjustments, like positioning your armrests. Before you move at all, buckle your seatbelt.

- Starting engine speed: Move the engine speed control to low idle and all hydraulic controls into neutral.

- Implement positions: Any attached tools and implements must be grounded before moving the vehicle.

- Before starting: If your skid steer features a Standard Display, wait until the cold starting aid alert indicator light turns off. If your equipment features an Advanced Display, wait for the Welcome screen to appear.

- Turn the key: Now you can finally turn the key start switch to start before cranking the engine.

Warming up and Moving the Machine

Here’s how to warm your skid steer up properly:

- Parking brake: Disengage the parking brake and run the engine at half throttle to allow the machine to warm up. The time required varies by model, so check your operator’s manual.

- Joystick controls: Hold your joystick control in the tilt-back position for 30 seconds, then release it. Hold the work tool joystick in the dump position for 30 seconds, then release it. Repeat this process for three minutes. Slowly move the skid steer to an open space and repeat this procedure while moving backward and forward for 10 feet, or about 3 meters.

Before moving the machine, release the handbrake, sound your horn and raise all attachments slightly off the ground. Smoothly move your speed and direction controls for your desired speed and direction.

How to Shut Down a Skid Steer

These are the steps you need to follow to shut your equipment down properly:

- Parking: Move and park your equipment on a smooth and level area. Move the joystick to neutral and engage the parking brake.

- Engine cooling: Move your speed control knob to low idle and keep it on this setting with no load for five minutes.

- Lower arms: Lower your machine’s loader arms and tilt the linkage until all work tools lay firmly on the ground.

- Hydraulic controls: Change your hydraulic controls to the neutral position.

- Battery: Turn off the battery disconnect switch until the “wait to disconnect” light has turned off.

- Dismounting: Ensure you exit following the three-point contact rule, which means you should always have two hands and one foot or two feet and one hand on the machine.

- Preparations for extended parking: If the skid steer will be stationary for an extended period, you should take some extra steps. Block the tires, remove the disconnect switch key and equip vandalism guards if applicable.

- Final step: Conduct a post-operation walk-around inspection of your skid steer.

How to Drive a Skid Steer

Various control schemes exist to operate a skid steer. These control schemes typically use a joystick or lever on the right and left sides. These are the most common control schemes:

- Standard pattern: This pattern uses dual steering levers to control the drive functions. Dual foot pedals control the lift and tilting functions. Push both levers forward to move forward and pull back to move backward. To turn left, push the left lever back and the right lever forward. Reverse these controls to steer to the right.

- H pattern: The H pattern is similar to the standard one. The main difference is handles that pivot or hinge to control the lift and tilt functions instead of pedals.

- ISO pattern: With this control scheme, the left joystick controls all the driving functions, while the right joystick controls the tilt and lift functions.

Skid Steer Safety

You may encounter several safety hazards when driving a skid steer. Knowing how to operate a skid steer properly does not eliminate the risk of these hazards. To ensure your safety, follow these skid steer safety protocols.

- Avoid hazards: Drive slowly to avoid hazards and ensure you have time to react to anything that might get in your way. You will have much more control by maintaining appropriate speed levels while driving the skid steer. A slower speed improves your reaction times and gives you more time to maneuver around hazards.

- Maintain visibility: Use reflective tape and wear reflective gear to stand out. Workers around the construction site should be able to spot the driver easily so they can get out of the way. Workers should also wear reflective gear so the driver can tell when someone is in the way.

- Load capacity: Do not overload your skid steer or exceed lifting capacities. Exceeding these limits can damage the equipment and risk tipping over. Rolling your skid steer is incredibly dangerous.

Personal Protection Equipment (PPE)

Make sure you wear the right PPE before driving a skid steer. Here’s what you should include:

- Head protection: Hard hats or helmets will keep your head safe from falling objects and protect you in case of an accident.

- Eye protection: Goggles, safety glasses or face shields protect your eyes from dust and debris.

- Hearing protection: Ear muffs reduce the noise of loud tools.

- Body protection: Safety vests and safety suits are reflective and padded to keep your body safe and make you more visible when vision is limited.

- Foot protection: Safety boots and slip-resistant footwear prevent you from falling and keep you safe if you step on sharp objects.

- Hand protection: Rubber and safety gloves protect your hands when working with large tools and electricity.

Stinger Attachments Knows How to Keep You Safe

Stinger Attachments knows everything about skid steers. We take pride in our high-quality products and services. To get the most out of your skid steer, you need to know how to operate it properly. Find the best skid steer attachments for your needs by browsing our extensive range of products.

Contact us to learn more about what we can do for you. You can also find a dealer on our website anytime to get advice on which product you should get.